Quattro Rally Build: Throttle body, power steering, alternator. Pick any two!

Posted on Mar 19, 2020

Throttle body, power steering, alternator. Pick any two!

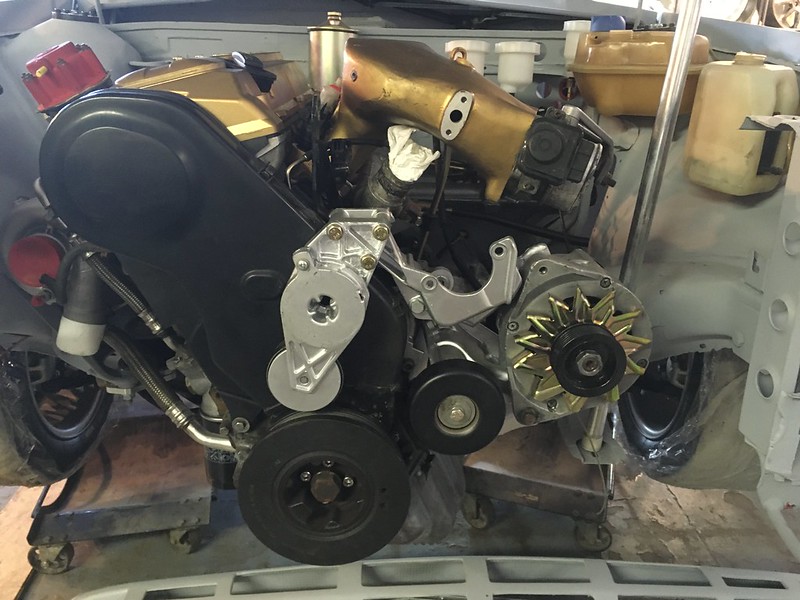

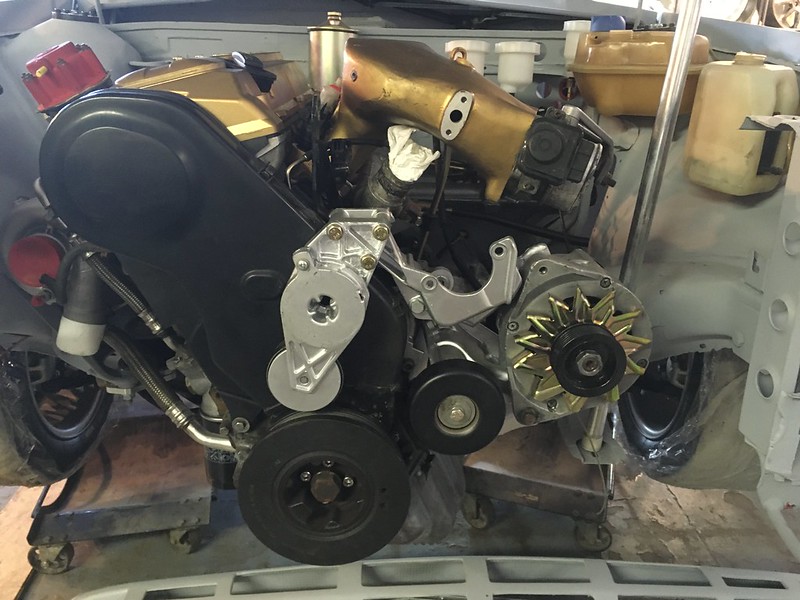

Yes, that's the conclusion we have come to trying to locate all the ancillary components in the engine bay. Right now, everything wants to be on the left side of the engine in front of the radiator. Remember, on these cars the radiator is not in front of the engine but to the side on the left. Because we are using an aftermarket intake manifold the throttle body is very close to the power steering pump. In fact, if we orient it correctly it is inside the power steering pump. We think we can rotate it 90 degrees and still mount it, though only one of the mounting holes lines up right now. Some adaptation will be necessary but we think we can make it work. Anyway, it has to be that way round to clear the hood and there is not really any room for an adapter. Even then, another issue is the outlet from the power steering pump still interferes with the throttle body, even after sourcing a really flat banjo bolt. Also, the outlet from the head coolant manifold is behind the power steering pump and very difficult to mount a pipe on. It's also heading in the wrong direction as it needs to end up behind the radiator. The coolant outlet from the block is also very tight where it passes the back of the power steering pump. Can we do without power steering?

Certainly, if we remove the power steering pump from the equation it creates some room but we are then left with an alternator stuck way out in front of the radiator and without much triangulation for the belt and no free length for the tensioner to push on. Maybe we should convert the power steering pump bracket to a second idler.

Another problem came up though: we can't seem to find a replacement alternator with the 200 amps or so we think we are going to need to power the six driving lamps and everything else.

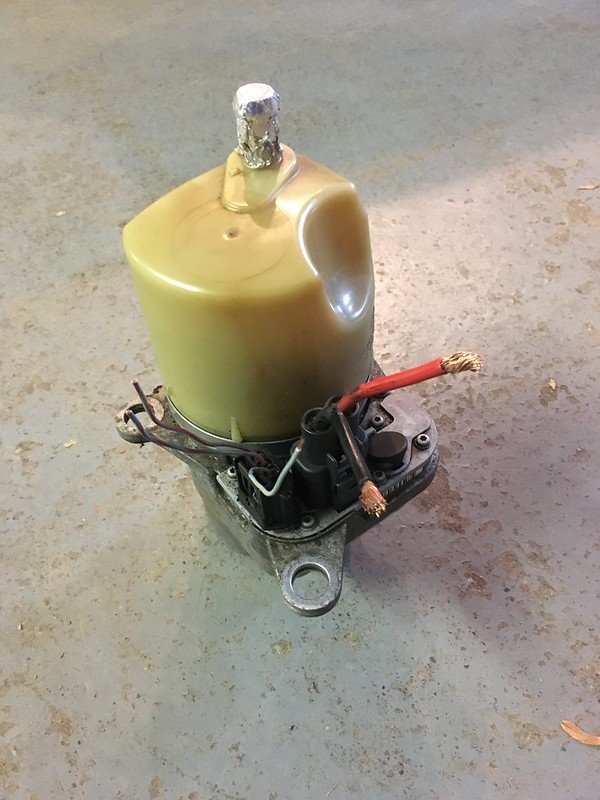

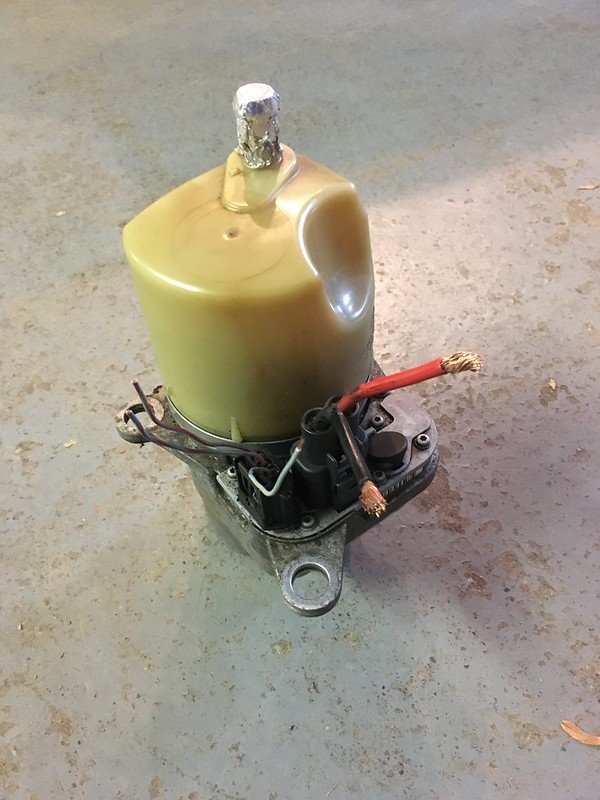

So now we have no power steering pump, no alternator and a throttle body that's held on with one bolt! What should we do? Well we think we have an elegant a solution. Firstly, why not use an electric power steering pump? They are readily available used from a variety of cars including Volvos, Toyotas etc. They can be mounted almost anywhere you can get lines and wires too as they obviously do not need a belt to drive them. They will also work even when the engine is not running which might be useful around the shop or if the engine blows up mid stage. Here’s an example of a Volvo unit.

Then we realized, if we are prepared to make a custom alternator bracket, we could use any 200 amp alternator from any vehicle. It just so happens that we have to make a custom bracket for the front engine mount on the other side of the engine and there is a nice alternator sized space doing nothing next to that. Why not source an inexpensive 200 amp remanufactured alternator from a Ford truck and mount it on the right side of the engine on a custom alternator/engine mount bracket?

These two solutions, if possible, will then result in us having only an intercooler outlet pipe in front of the radiator which can’t be a bad thing for cooling air flow, right?

Subscribe to find out if any of these work out or if we go back to the drawing board.

Yes, that's the conclusion we have come to trying to locate all the ancillary components in the engine bay. Right now, everything wants to be on the left side of the engine in front of the radiator. Remember, on these cars the radiator is not in front of the engine but to the side on the left. Because we are using an aftermarket intake manifold the throttle body is very close to the power steering pump. In fact, if we orient it correctly it is inside the power steering pump. We think we can rotate it 90 degrees and still mount it, though only one of the mounting holes lines up right now. Some adaptation will be necessary but we think we can make it work. Anyway, it has to be that way round to clear the hood and there is not really any room for an adapter. Even then, another issue is the outlet from the power steering pump still interferes with the throttle body, even after sourcing a really flat banjo bolt. Also, the outlet from the head coolant manifold is behind the power steering pump and very difficult to mount a pipe on. It's also heading in the wrong direction as it needs to end up behind the radiator. The coolant outlet from the block is also very tight where it passes the back of the power steering pump. Can we do without power steering?

Certainly, if we remove the power steering pump from the equation it creates some room but we are then left with an alternator stuck way out in front of the radiator and without much triangulation for the belt and no free length for the tensioner to push on. Maybe we should convert the power steering pump bracket to a second idler.

Another problem came up though: we can't seem to find a replacement alternator with the 200 amps or so we think we are going to need to power the six driving lamps and everything else.

So now we have no power steering pump, no alternator and a throttle body that's held on with one bolt! What should we do? Well we think we have an elegant a solution. Firstly, why not use an electric power steering pump? They are readily available used from a variety of cars including Volvos, Toyotas etc. They can be mounted almost anywhere you can get lines and wires too as they obviously do not need a belt to drive them. They will also work even when the engine is not running which might be useful around the shop or if the engine blows up mid stage. Here’s an example of a Volvo unit.

Then we realized, if we are prepared to make a custom alternator bracket, we could use any 200 amp alternator from any vehicle. It just so happens that we have to make a custom bracket for the front engine mount on the other side of the engine and there is a nice alternator sized space doing nothing next to that. Why not source an inexpensive 200 amp remanufactured alternator from a Ford truck and mount it on the right side of the engine on a custom alternator/engine mount bracket?

These two solutions, if possible, will then result in us having only an intercooler outlet pipe in front of the radiator which can’t be a bad thing for cooling air flow, right?

Subscribe to find out if any of these work out or if we go back to the drawing board.